CHROMIUM COPPER (CrCu)

|

Chromium Copper, having plenty of Hardness, Electric Conductivity and Heat Conductivity is widely available for spot welding on general soft steel board.

Chromium Copper is quite suitable as main material for Shanks, Adapters, Holders and back bar electrodes, etc in addition to Cap Tips. |

ALUMINA DISPERSION STRENGTHENED COPPER (Al2O3Cu)

|

Alumina Dispersion Strengthened Copper is better in hardness, electric conductivity and heat conductivity than that of Chromium Copper.

The high heat resistance given by Alumina prevents from work-pasting and work-sticking while welding. Consequently, this material is best suited to welding steel plate surface processed, low pressurized thin steel plate and electric parts which are consist of Aluminum lead wire, etc. |

M2

|

| M2 is a material which is compounded Zirconium and other elements to Chromium Copper. In comparison to Zircochromium Copper, M2 has a much harder material. SMK's newly developed products coated with a special tratment are used mainly for Cap Tips because of its high quality, longevity and tendency to stick less.. |

MCZ

|

| MCZ is the material produced by compounding Chromium Copper with Zirconium and Silicone. In comparison to Chromium Copper, MCZ have a much stronger hardness and low wear performance. For this reason, MCZ is widely used for Cap Tips |

MEASUREMENT

|

| Since the inner diameter taper parts of tips may slightly differ among manufactures, we recommend you to use the SMK standard shanks. As the dress line position shows the bottom of the water hole position, please make use of this point as a guide line when grinding the tips. |

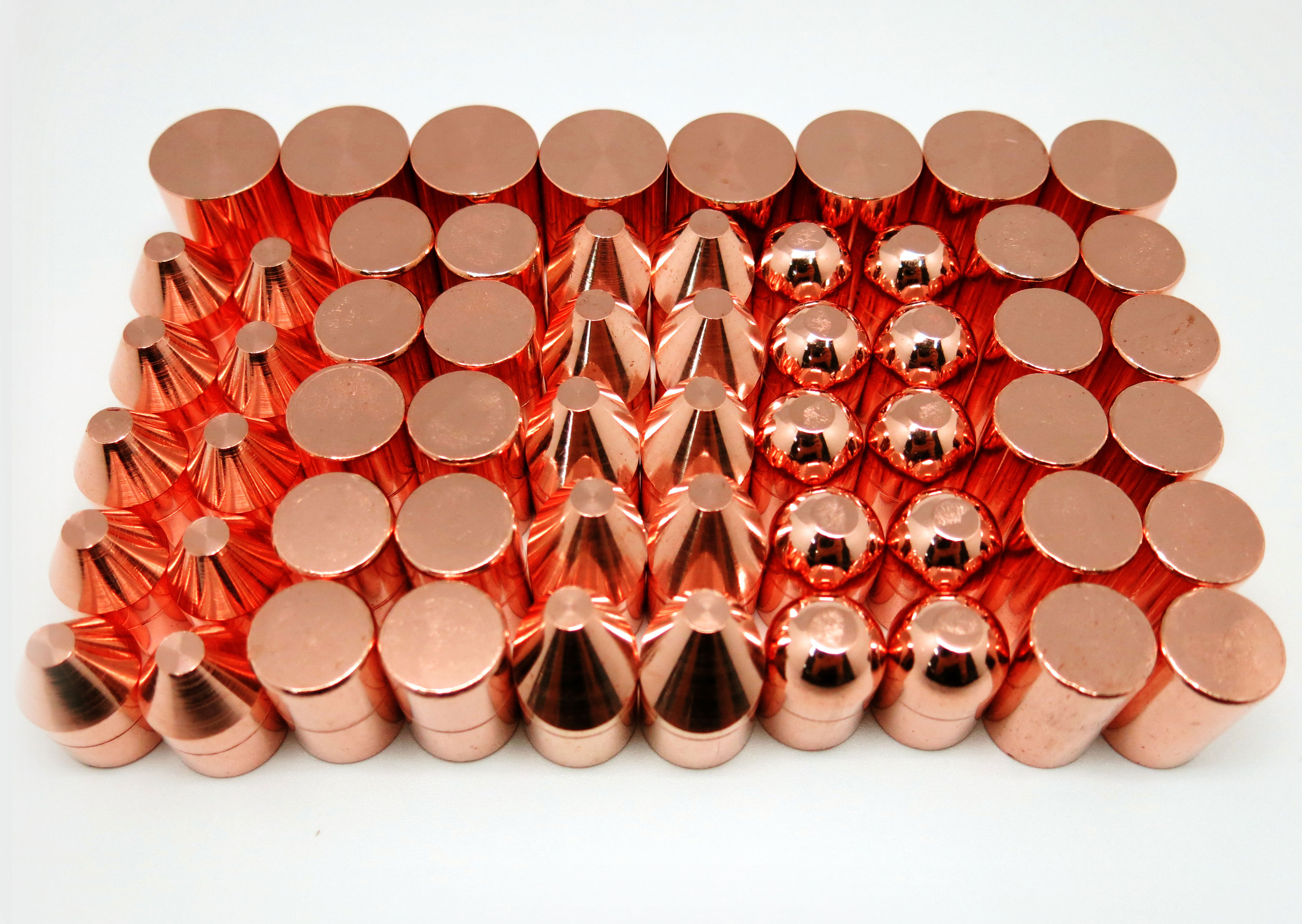

TOP FORM OF CAP TIP

|

Please choose one based on your welding conditions and work-piece-forming.

D type, R type and P type are the most generally used. |

All automation

All automation

All edogawa metals

All edogawa metals

All main products

All main products